Transport infrastructure represents enormous capital investments that typically operate for decades once constructed. A new highway system might cost several billion dollars and remain in service for fifty years. A rail transit network might involve billions in capital investment for similar operational lifespans. A port terminal reconfiguration might require hundreds of millions in investment. Given the scale of these investments and the lengthy operational horizons, making optimal decisions becomes critically important. A facility designed sub-optimally performs poorly for decades, preventing the organization from recovering from the initial decision mistake. Conversely, a facility designed optimally delivers benefits across its entire operational life.

Traditionally, infrastructure planning relied on engineering judgment, historical precedent, and mathematical models predicting how systems would perform. While these approaches work reasonably well, they suffer from inherent limitations. Complex system interactions that are difficult to predict mathematically can surprise planners. Unforeseen operational issues that designers did not anticipate create problems. Opportunities for optimization that would have been obvious through actual system operation go unrecognized at the design stage. Digital twin technology represents a transformative evolution in transport infrastructure planning by enabling detailed virtual simulation of how proposed systems and modifications would actually perform.

Virtual Replication and Comprehensive System Modeling

A digital twin is a virtual replica of a physical system that incorporates both the static physical characteristics and the dynamic operational processes. For a transport system, this means capturing the physical infrastructure roads, tracks, terminals, equipment as well as simulating how people, vehicles, and cargo move through the system. A digital twin of a port includes the physical layout of berths, storage areas, and transportation corridors, but also simulates vessel movements, cargo flows, equipment operations, and workforce movements.

Building a comprehensive digital twin requires detailed spatial data, operational rules, and behavioral models. Three-dimensional laser scanning or drone imaging captures the physical geometry of existing infrastructure. Building information modeling (BIM) software organizes this spatial data with material properties, structural information, and operational systems. Real-time sensor feeds provide actual operational data traffic volumes, equipment utilization, processing times, queue lengths. Simulation software models the movement of people, vehicles, and cargo through the system, responding to operational rules, resource constraints, and demand variations.

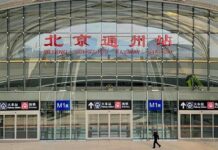

The result is a virtual environment where planners can simulate operations before implementing physical changes. A transportation authority can simulate how a proposed new rail station affects traffic flows, passenger patterns, and system balance. A port can simulate how a new cargo handling facility affects throughput, equipment utilization, and vessel turnaround times. An airport can simulate how additional gates affect passenger flows, security line lengths, and aircraft servicing efficiency. These simulations reveal performance implications that would be impossible to predict through analysis alone.

Testing Infrastructure Modifications and Design Alternatives

One of the most valuable applications of digital twins involves testing how proposed infrastructure modifications would affect system performance. Rather than making billion-dollar decisions based on static analysis, planners can observe how proposed changes actually perform through detailed simulation.

Consider a city planning to add a new rail line to its transit network. A digital twin enables planners to simulate exactly how the new line would affect:

System balance and ridership distribution across existing and new routes. Traffic patterns on roads as some drivers shift to transit. Pedestrian movements and congestion around new stations. Equipment utilization across the expanded network. Operating costs for the expanded system. Revenue impacts from shifted demand patterns. Equity implications for different neighborhoods and demographic groups. Environmental impacts from reduced vehicle travel.

The simulation can test variations in station locations, frequency of service, fare pricing, and integration with other transit modes. Planners can observe how different design choices affect system performance before committing to physical construction. If a proposed station location creates bottlenecks in passenger flows, the simulation reveals this immediately, and the location can be adjusted. If the proposed service frequency leaves certain routes congested while others operate at low utilization, the simulation shows this, and frequency allocations can be optimized.

For a port evaluating a major facility reconfiguration, digital twin simulation reveals how the proposed changes would affect cargo throughput, equipment utilization, vessel turnaround times, truck flows, and operating efficiency. A port might evaluate several alternative configurations, each carefully designed based on operational experience. The digital twin enables comparing these alternatives objectively, revealing which design achieves optimal performance across multiple dimensions.

Predictive Maintenance and Lifecycle Degradation Modeling

Transport assets vehicles, tracks, equipment, facilities degrade continuously through wear, corrosion, environmental exposure, and operational stress. The rate of degradation varies depending on environmental conditions, operational intensity, maintenance quality, and other factors. Predicting when specific assets will require major maintenance or reach end-of-useful-life is challenging but critical for lifecycle planning.

Digital twins incorporate real-time sensor data about asset condition vibration levels, structural deformation, surface corrosion, material fatigue and apply degradation models learned from historical data. The system tracks how individual assets age under actual operating conditions. A bridge digital twin incorporates real-time strain measurements, crack detection, corrosion monitoring, and traffic loading data. Degradation models predict how these factors combine to affect structural integrity. The system forecasts with high accuracy when the bridge will require major rehabilitation or need replacement.

This predictive capability transforms lifecycle management. Rather than replacing assets on fixed schedules or waiting until failure occurs, organizations can schedule replacements based on actual condition predictions. A transit authority can forecast that specific vehicle components will require replacement in 18 months, allowing advance budgeting and spare parts acquisition. A railway can predict that specific track sections will require major rehabilitation in 24-36 months and can plan track work to minimize disruption. An airport can forecast when specific runway pavement sections will require overlay based on degradation patterns and aircraft traffic.

The business impact is substantial. Lifecycle events can be scheduled during periods of low operational impact rather than occurring unexpectedly during peak demand. Capital expenditures become more predictable and can be budgeted strategically across years. Asset replacement timing optimizes lifecycle costs rather than replacing assets prematurely or allowing them to degrade to costly failure. Organizations gain unprecedented visibility into their asset portfolios, enabling strategic decisions about whether to maintain, refurbish, or replace specific assets.

Risk Reduction and Uncertainty Management

Major infrastructure investments involve substantial risk. Designs that perform poorly once implemented remain problematic for years. Construction delays increase costs. Operational difficulties that emerge after opening create expensive retrofits. Digital twins reduce these risks by enabling detailed analysis and testing before physical implementation.

Engineers can stress-test proposed designs against extreme scenarios—unusual weather conditions, demand spikes, equipment failures, traffic incidents. If the design fails under certain stress conditions in simulation, it can be improved before physical implementation. If certain equipment failures would cascade into network-wide disruptions, the design can be modified to improve resilience. If capacity margins prove inadequate during peak demand, the design can be expanded.

This testing capability is particularly valuable for complex transport systems where system interactions are difficult to predict. Modifying one component affects others in ways that might not be obvious. Adding capacity at one point might simply shift congestion to another location. Improving traffic flow on one route might increase congestion on parallel routes. Digital simulations reveal these dynamic interactions, enabling designs that optimize overall system performance rather than optimizing individual components in isolation.

Optimizing Utilization and Operational Efficiency

Beyond planning new infrastructure and predicting degradation, digital twins enable continuous operational optimization. Simulation of alternative operating strategies reveals which approaches maximize throughput, minimize costs, or achieve other operational objectives. A port can simulate different cargo handling procedures, equipment allocation strategies, and vessel scheduling approaches to identify the combination that maximizes cargo throughput while minimizing equipment wear and cost. A transit authority can simulate different frequency allocations, schedule timing, and route configurations to optimize ridership, operating efficiency, and equity across service areas.

These operational optimizations are not one-time exercises. As conditions change—demand patterns shift, new equipment is introduced, facilities are expanded—the digital twin can simulate new operational strategies optimized for the new environment. Organizations operating transport systems with digital twin support achieve measurable improvements in operational efficiency, higher utilization of expensive assets, and better optimization of performance across multiple objectives.

From Prediction to Performance Assurance

The ultimate value of digital twin technology in transport planning and asset management lies in its ability to provide performance assurance. Rather than hoping that infrastructure performs as intended, planners know how it will perform because they have simulated it thoroughly. Rather than discovering operational problems after opening, problems become apparent through simulation and are addressed before facilities are operational. Rather than being surprised by asset degradation timing, organizations know when maintenance and replacement will be needed.

This shift from uncertain prediction to performance assurance represents a fundamental improvement in how transport infrastructure is planned, operated, and maintained. Transport organizations using digital twin technology invest more effectively, operate more efficiently, maintain assets more strategically, and adapt more readily to changing conditions. For passengers and cargo using these systems, the result is infrastructure that performs reliably, accommodates their needs effectively, and continues serving well throughout its design life.